Jan2024

Electric Flange Heaters

Process Technology’s Flange Electric Heaters are versatile, efficient, direct, compact, standalone, cost-effective, and emissions-free solutions that meet diverse industrial process heating needs. They are crucial in heat transfer applications, freeze control, and temperature regulation. Let’s explore their significance and key features.

SIGNIFICANCE OF ELECTRIC FLANGE IMMERSION HEATERS

Flanged immersion heaters are indispensable in industrial processes, ensuring efficient, environment friendly heat transfer, freeze prevention, instant heat, and precise temperature control. They find applications in seawater desalination, heating oil and gas turbines, thermal oil vaporization, furnace heating, and water tank heating.

Flange Immersion Heaters Offer Essential Heat

Flange immersion heaters provide essential heat for various demanding and diverse seamless industrial processes, indirectly impacting our daily lives. They contribute to reducing waste and producing valuable byproducts from industrial processes, making them vital in our lives.

Key Features of Flange Heating

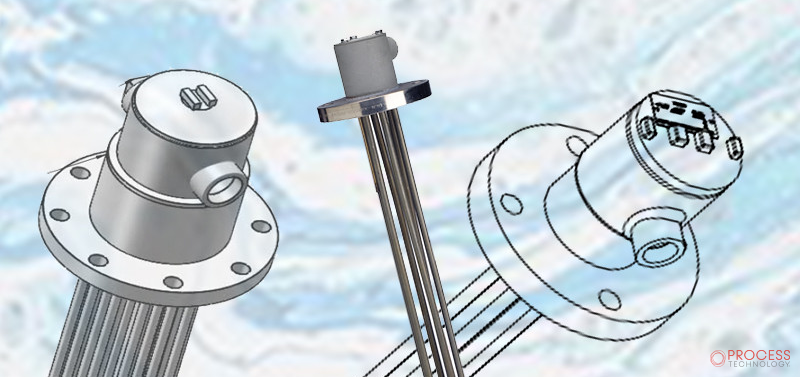

Process Technology’s Electric Flange Heaters are favored for various industrial environments, including water, air, solvents, and oil heaters. They come in various models tailored to specific heating requirements. These heaters comprise a cylindrical heating element with wire-like pins arranged in a flange-shaped configuration, offering user-friendliness and cost-effectiveness.

Process Technology’s “Plug & play” ready-to-use flange heaters are available in different sizes, heating duties, and flange specifications; the number of Flange Heaters required depends on power and wattage density requirements. They can be immersed directly into the liquid needing heating, with control outside the tank for easy regulation.

Most models include a thermocouple for precise temperature monitoring, making Flange Heaters ideal for rapid and efficient heat transfer in industrial processes.

Applications of Flange Immersion Heaters

Flange heaters offer heating solutions for liquids, including oil, water, chemical solvents, corrosive solutions, process air and gases in hazardous as well as safe industrial settings. They regulate temperatures of various solvents and gases, finding use in gas turbines, desalination, vaporization, crude oil heating, biogas and more.

Constructed from special alloy combinations, the sheath offers moisture and corrosion protection, enhancing durability. They have various mounting options for easy installation in large reservoirs, boilers, process vessels, and water tanks. Known for their ease of operation and minimal maintenance, they contribute to reduced operational costs.

FLS SERIES FLANGED HEATER BY PROCESS TECHNOLOGY

Durable, efficient chemical heater.

Heavy wall metal sheaths are available in 316 stainless steel and titanium. 316 Stainless Steel standard with metal explosion-resistant M2 terminal enclosure. In a range of flange sizes. 3000-72000 watts, 208-600 volts.

FLX SERIES FLANGE HEATER BY PROCESS TECHNOLOGY

Excellent chemical resistance to aggressive acids.

Heavy wall fluoropolymer sheath (PTFE) covered stainless steel element reduces permeation. Excellent chemical resistance to aggressive acids! Inert to most solutions with a corrosion-resistant head. Thermal protector built-in. 3″ and 6″ flange sizes. 1000-18000 watts, 120-600 volts.

In summary, Process Technology’s Flange Heaters are indispensable assets in industrial processes, offering versatility, durability, and ease of use. Their role in achieving precise temperature control and efficient heating in diverse industrial settings cannot be overstated.